SmartSDR v3.7.4 and the SmartSDR v3.7.4 Release Notes | SmartSDR v2.12.1 and the SmartSDR v2.12.1 Release Notes

SmartSDR v1.12.1 and the SmartSDR v1.12.1 Release Notes

Power Genius XL Utility v3.8.8 and the Power Genius XL Release Notes v3.8.8

Tuner Genius XL Utility v1.2.11 and the Tuner Genius XL Release Notes v1.2.11

Antenna Genius Utility v4.1.8

Need technical support from FlexRadio? It's as simple as Creating a HelpDesk ticket.

Power Pole connectors

They were inserted to their max, but continue to fall out.

Is this the way they work or a failure?

Can another power connector be substituted that more reliable?

Thanks Tom W3FRG

Answers

-

Work-Around #1:

Since removing and replacing the power connectors may void your warranty, a decent

Work-Around for now is as follows:

Run your rigs DC power cord through a "one hole" nylon cable clamp, and attach that

clamp to the rigs ground connector on the back panel.

REF: https://www.ebay.com/sch/i.html?_nkw=nylon+cable+clamp&_sacat=0

No argument, Flex has SO MUCH space in that chassis, that they really should have used

a locking molex connector like all the other vendors do, with locking connector on the rig

end, and Anderson power poles on the remote cable end.

Cheers,

Neal

3 -

I'm changing the one on my 6500 as soon as warranty runs out.

Never have liked power pole connectors, on anything.

0 -

Yes, Please consider. Power Pole connectors are undependable0

-

The Nice Thing about the Power Pole Connector is you can get them at almost ANY AUTOMOTIVE supply store! The ones for Yaesu, Kenwood, Icom, pre made are expensive and only available at Electronic stores or Ham Stores, or eBay...

Most DC Power Splitter/Terminals used to feed the power from your Astron PS to multiple radios use the same terminals on the Power Block.

So for me, I was personally Happy Flex went in this direction, so now I can switch DC power from a Astron Power Supply to my Motor Home Solar System.. All my cables are custom built, by me, with the length of the DC cable custom to fit the application... Also, this allows adding two In Line Fuses..

Mine always fit Tight, so not sure about your situation..

Robert

1 -

Funny how some of us are the exact opposites...

I really like Power Poles... in fact, when I still owned ICOM HF rigs I converted the Icom's to Power Poles for easy swapping of radios. In fact one of the issues I had with Molex is that they were so hard to disconnect in hard to reach places...

All my various VHF/UHF radios are also Power Poles..

Never really had an issue with Power Poles as they always seem to fit tight enough even for vibrating environments in vehicles...

I live near the ocean with a relatively corrosive high salt environment... a bit of Deox-it and the occasional reseating does wonders to keep things 100%

3 -

No power poles plug together tightly, this is not normal. But maybe the power cord you are using is stiff?0

-

I hate Power Poles also. I can guarantee there are non of these in first responder vehicles.0

-

BUT Every Emergency Operating Center (EOC) I have seen in SoCal seems to have standardized on Power Poles...

1 -

I have never had any trouble with my connectors,,complain as we want,,this is how it's done on on our radios, make it work.1

-

This is the cord supplied by Flex with the 6600M.

There appears to be no locking mechanism on these connectors, they just slip on.

And more easily, slip off.

Tom W3FRG

0 -

hmmm I have to really pull on mine to get them off1

-

My home brew dc cable does not come out easily. It’s secure and I’ve not had any issues except when I did a sloppy install of the cable pp connectors. However, keeping the connectors out of tension seems a good approach to better reliability.0

-

Tom,

Your problem with the Power Poles is easily rectified. Since the metallic connectors fall out, do this: Make sure the current carrying ends (the little **** at each end) are parallel with the wire crimp area - they should be relatively straight except for the curved current humps on the ends. Next, look inside the plastic housings that the metal pieces fell out of. Inside of the narrower portion of the plastic housing on the end that plugs into the Flex, you will see a piece of flat metal. This is spring steel. Take a small screwdriver and pry the flat spring steel upward toward the center of the plastic housing. It doesn’t take a lot. the spring steel should be showing a little above the edge of the plastic housing. Do this for both the black and red housings. Re-insert the connectors from the rear of the housings; they should be slightly difficult to insert, but once inserted properly, they should lock into the plastic housings and the electrical connectors should be very near to the end of the housings. You should NOT be able to pull out the connectors by pulling on the wires. plug it into the radio and all should be OK.

And, yes, I am not a fan of Power Poles, either, but since the EMCOMM community has standardized on them, I’ve learned to deal with them and make adjustments when necessary.1 -

What is your secret?

These slip off like they were greased.

No effort at all and they fall off.

Tom W3FRG

0 -

See my reply at the end of this thread - N8GD0

-

Greg,

Tnx for the input. Sounds like that's the issue, making solid contact.

I'll give it a try and report back.

Tom W3FRG

0 -

The spring steel pieces not only hold the electrical connectors in place, they also provide upward pressure against the contacts to make the proper mechanical and electrical connection.

0 -

I wish FRS used these connectors for DC power. Power poles work OK but don't have a good mechanical connection.

http://www.neutrik.com/en/powercon-20a/

0

0 -

The pin on the power poles must be full inserted. If not they will come out easily.

2

2 -

Normally my power-poles make solid connections however the 6600 is an exception. When mounted on a shelf rack (ears to come) the power cord falls out with the slightest motion.

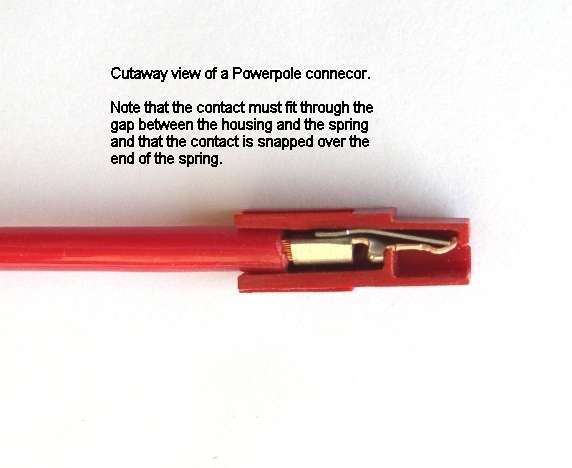

As per the above cutaway, with any loose connector I bend the spring to increase the resting tension.0 -

Great graphic to show how to make proper Power Poles electrical connector insertion. Getting the blade through that little slot next to the spring steel can be difficult, and probably is one cause for the wire and electrical connector being easily pushed out. You MUST see the end of the metal electrical connector near the opening in the front (indicating it is locked) or it will be pushed out when mated with the matching plug. If you see the spring only, it’s not right!

0 -

With all of this said about PP connectors and how great they are, its possible that the FRS supplier of their PP power cord assemblies has an issue with assembly??

Tom W3FRG

0 -

Mike-VA3MW Administrator, FlexRadio Employee, Community Manager, Super Elmer, Moderator adminOptionsFor those of you having issues keeping your powerpoles in place, why not strap (tie) the power lead to the ground **** with something. Even string will work.

Mike-VA3MW Administrator, FlexRadio Employee, Community Manager, Super Elmer, Moderator adminOptionsFor those of you having issues keeping your powerpoles in place, why not strap (tie) the power lead to the ground **** with something. Even string will work.

I would not modify the radio for many reasons, the biggest one being would be the impact on the resale price of your radio should you choose to sell it.

ymmv

Mike va3mw0 -

Hi Mike,

If we're going to improvise to get the PP connectors to stay in place, why not a dab of RTV around them to the radio which can readily be removed later on w/o any damage to the radio or connector.

But, since the above is truly a placeholder, till the real culprit is ID'd, and based on near perfect manufacturing of the plastic and metal parts from PP, it points to an assembly, or inspection issue, somewhere along the line.

Tom W3FRG

0 -

For power connections around the shack (AC or DC) - I've always tried to use some mechanism to ensure a "service loop". I use these Hellermann Klam-Klips quite a bit. They come in all different sizes. In aviation wiring they not only require service loops for mechanical shock & vibration, but also to act as "drip loops" to ensure that condensation would normally move away from the avionics.

I know it's not a space launch - but I would guess the klips, or something similar, would help in the event you like your shack wiring banjo-string tight.

73 Jim, WQ2H

2 -

Mike-VA3MW Administrator, FlexRadio Employee, Community Manager, Super Elmer, Moderator adminOptionsHi Tom

Mike-VA3MW Administrator, FlexRadio Employee, Community Manager, Super Elmer, Moderator adminOptionsHi Tom

Yep. I personally have never had any issue with them and they have never fallen out for me on my 6300 or 6600. On my mobiles, different story and I use XT60's from the RC Plane world since they are tank proof and very very inexpensive.

The hobby somehow decided to make these a standard and so it is.

73

0 -

Yup, did that more than once. Thinking of purchasing the insertion/extraction tool DX Engineering has.0

-

As you can see by this thread, the one HUGE problem with Anderson Power Poles is inconsistent reliability (sic).

There are a combination of many suppliers, some selling actual Anderson product, and many selling

China look-alikes. The manufacturing tolerance of perhaps a few thousandths of an inch make the

difference between a tight connection, and one that falls out.

I personally have had power poles that I almost could not pull apart by hand, and other cables

that come off WAY too easy. I have also had 3 separate situations where the connection was

intermittant, too much manufacturing tolerance so that the two metal blades in each cable

end would not fully/reliably engage. That was fun. Solution was to either cut off the set and crimp

new power poles on, or to bend the shape of the blades and re-insert them in the shell.

[NOTE: I NEVER had to do this with Molex connectors.]

Even the RC model airplane industry uses a far better, higher current "bullet connector".

Ref: https://www.ebay.com/sch/i.html?_nkw=RC+bullet+connector&_sacat=0

I use the strain relief as I suggested earlier, but I really wanted to "counter-point" all the

people saying they never had any problem with Anderson Power Poles. If you have not,

then you simply are not a heavy user with lots of devices using the power poles.

Because if you have, honestly, 18 to 25 devices in the shack using power poles, you

indeed will experience what I have. Not my favorite connector, but I can live with it.

Neal0 -

I have at least 25 devices (probably more like 50) in my shack that use Power Pole Connectors.

I DO NOT HAVE ISSUES

Why?

Because

1.I bought professional grade crimping and insertion tools,

2. I made all the connections myself.

3. I use Anderson Branded (Not Chinese that they Sell at HRO) Connectors

4. I use Deox-It and,

5. Where possible I put strain relief ties.

I got forced in Power Poles about 15 years ago when I volunteered for ARES EMCOM duties and had to make all my radios compatible with the EOC.. The EOC does not have issues either.

It just takes a bit of care to get it right.

Bottom Line: I am very happy with my Power Poles and I am glad I was forced to switch

4 -

Not my favorite connector, either, but, as I stated earlier, the EMCOMM crowd adores these highly intermittent connectors.

I have had many problems with poor connectivity between the metal electrical conductor blades, even at a "low" 5 Amp draw. I've seen 0.5 to 1.0 volt drop on these connectors at the 5 AMP level. I strongly suspect that many Flex users who have low transmit power levels are victims of poor Power Pole conductivity. Since you're stuck with them on the radio, the only fix is to bend the steel springs and hope for a better connection. I also suspect that the electrical connector blades themselves become oxidized/corroded and prevent good conductivity. They appear to be silver plated, but I'm not sure. Poor conductivity either because of oxidation/corrosion or bad tension makes Power Poles not a good choice in my estimation.0

Leave a Comment

Categories

- All Categories

- 246 Community Topics

- 2.1K New Ideas

- 488 The Flea Market

- 7.3K Software

- 5.9K SmartSDR for Windows

- 134 SmartSDR for Maestro and M models

- 328 SmartSDR for Mac

- 241 SmartSDR for iOS

- 224 SmartSDR CAT

- 161 DAX

- 343 SmartSDR API

- 8.5K Radios and Accessories

- 6.9K FLEX-6000 Signature Series

- 768 Maestro

- 42 FlexControl

- 836 FLEX Series (Legacy) Radios

- 726 Genius Products

- 391 Power Genius XL Amplifier

- 251 Tuner Genius XL

- 84 Antenna Genius

- 222 Shack Infrastructure

- 149 Networking

- 370 Remote Operation (SmartLink)

- 118 Contesting

- 582 Peripherals & Station Integration

- 116 Amateur Radio Interests

- 810 Third-Party Software